Introduction

White cast iron is one of the most durable and wear-resistant types of cast

iron used in industrial applications. Known for its bright, white fracture

surface and exceptional hardness, it plays a crucial role in equipment that

faces constant abrasion and surface wear. But what exactly is white cast

iron? How does it compare to other types of cast iron

like gray or ductile

iron? And why is it said to be non-weldable?

In this guide, we'll explore the properties, advantages, common uses, and

care tips for white cast iron—along with one of its most important

limitations: why it cannot be welded.

What Is White Cast Iron?

White cast iron is a unique type of cast iron known for its extreme hardness

and excellent wear resistance. Unlike other types of cast iron, it gets its

name from the bright, white fracture surface it exhibits when broken—caused

by the presence of iron carbide (cementite) in its microstructure.

Why It’s Called “White” Cast Iron

When fractured, white cast iron breaks with a glossy, silvery-white

surface due to the absence of free graphite. This feature differentiates

it visually and mechanically from gray

cast iron.

White Cast Iron Microstructure

White cast iron is defined by its cementite-rich microstructure, which gives

it extreme hardness but also makes it brittle. Unlike gray cast iron, it

lacks graphite and contains carbon in the form of iron carbide (Fe₃C).

Composition and Structure

White cast iron contains a high percentage of carbon and

silicon—typically around 2.0–3.3% carbon and 0.5–1.9% silicon. The

carbon exists predominantly as cementite rather than graphite, resulting

in a bright white fracture surface and low ductility. This

microstructure contributes to its excellent wear resistance and poor

machinability.

Key Properties of White Cast Iron

High Hardness and Brittleness

White cast iron is extremely hard due to its cementite-rich composition,

making it very resistant to wear. However, this same property also makes

it very brittle, limiting its use in applications where impact or

tensile strength is required.

Excellent Wear Resistance

This material excels in abrasive conditions. It's commonly used where

materials need to withstand constant grinding, scraping, or erosion.

Thermal Conductivity and Limitations

White cast iron has decent thermal conductivity but can suffer from

thermal shock due to its brittleness. It’s not ideal for applications

with rapid temperature changes or tensile stresses.

Benefits of Using White Cast Iron

Ideal for Abrasive Environments

Thanks to its hardness, white cast iron is perfect for equipment that

deals with sand, gravel, ore, or other abrasive materials.

Cost-Effective for Specific Applications

It's economical to produce and ideal for use in short lifespan or

replaceable components, like liners and hammers in crushing equipment.

Long Service Life with Proper Use

In the right conditions (abrasive, compressive environments), white cast

iron offers a remarkably long service life with minimal wear and tear.

Common Applications of White Cast Iron

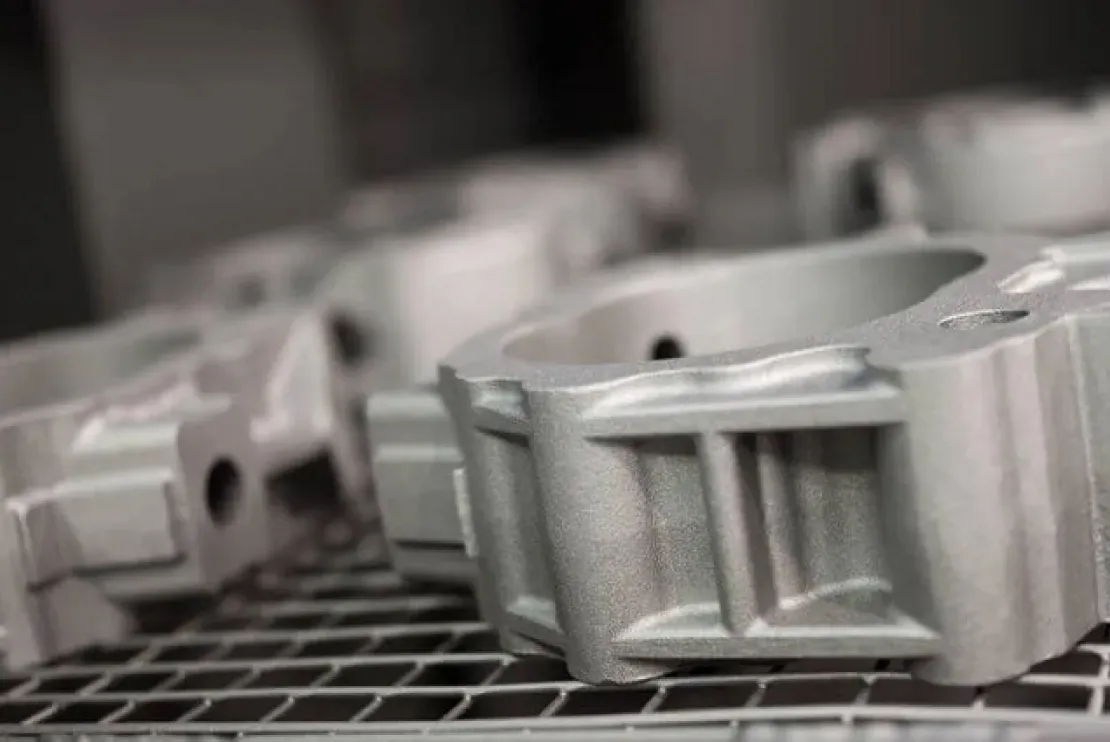

Crushing and Grinding Equipment

Used extensively in jaw crushers, grinding mills, and pulverizers, white

cast iron is able to endure the intense friction of mineral processing.

Pump Liners and Mill Linings

These components benefit from white cast iron’s resistance to slurry

erosion and abrasive particles.

Brake Shoes and Wear Plates

The automotive and industrial sectors use white cast iron in brake

systems and sliding parts due to its reliability.

Industrial Machinery Components

Various heavy-duty machine parts, like cams, rolls, and cutting edges,

are made from white cast iron to enhance durability.

White Cast Iron vs Gray Cast Iron

Differences in Composition

Used extensively in jaw crushers, grinding mills, and pulverizers, white

cast iron is able to endure the intense friction of mineral processing.

- White Cast Iron: High

cementite, no free graphite

- Gray Cast Iron: Contains graphite flakes

Mechanical Properties Comparison

| Property |

White Cast Iron |

Gray Cast Iron |

| Hardness |

Very High |

Moderate |

| Ductility |

Very Low |

Moderate |

| Machinability |

Poor |

Good |

| Wear Resistance |

Excellent |

Moderate |

| Tensile Strength |

Low |

Moderate |

Use Case Scenarios

- Use white cast iron for abrasive and wear-heavy applications.

- Choose gray cast iron for vibration damping, machinability, and

general casting.

Limitations of White Cast Iron

Brittle Nature

Its inability to flex or absorb shock makes white cast iron unsuitable

for dynamic or load-bearing components.

Difficult to Machine

Due to its hardness, machining white cast iron requires specialized tools

and techniques. Post-casting modifications are limited.

Not Suitable for High Tensile Loads

While excellent under compression, white cast iron fails quickly under

tension, making it a poor choice for structural applications.

Why White Cast Iron Cannot Be Welded

The Science Behind the Limitation

White cast iron contains a high amount of cementite, a very hard iron

carbide. When heated during welding:

- Cementite decomposes, releasing free carbon

- Free carbon migrates into the heat-affected zone (HAZ)

- This leads to brittle microstructures and cracking

Common Problems with Welding White Cast Iron

- Cracking during or after cooling

- Poor fusion of base and filler metal

- Very brittle and unreliable weld joint

Alternatives to Welding

Instead of welding, engineers often:

- Replace the part completely

- Use mechanical fastening methods

- Design systems for modular component replacement

How to Maintain and Care for White Cast Iron

Operating Conditions to Watch

Keep white cast iron away from impact loads and thermal shocks. Use it in

environments where pressure is compressive and steady.

Cleaning and Storage Guidelines

Clean parts using non-abrasive methods. Avoid rapid heating or cooling

during maintenance, as temperature swings may cause cracking.

Avoiding Thermal Shock and Impact Loads

Ensure that white cast iron components are not exposed to sudden

temperature changes, and protect them from mechanical shocks or heavy

drops.

Conclusion: Engineered for Trust and Safety

White cast iron is a specialized material, not a universal one. Its

outstanding hardness and abrasion resistance make it a top performer in

mining, grinding, and wear-prone machinery. However, its brittleness,

non-weldability, and poor machinability mean it must be used carefully and

for the right applications.

If your needs involve high wear, low impact, and compressive stress, then

white cast iron is a smart, long-lasting solution. But for flexibility,

weldability, or shock resistance, you'll want to explore other iron alloys

like ductile or malleable cast iron.

Choose wisely—and your equipment will thank you.