Introduction

Ductile iron and cast iron are pivotal materials in various industries, each

possessing distinct characteristics that can significantly impact the

success of a project. Understanding the importance of selecting the right

iron alloy is crucial for ensuring structural integrity, longevity, and

cost-effectiveness. In this exploration, we delve into the key attributes of

ductile iron and cast iron, aiming to shed light on their unique qualities.

By undertaking a comparative analysis, we aim to guide you in making

informed decisions tailored to the specific demands of your applications.

Join us as we unravel the intricacies of ductile iron vs. cast iron, paving

the way for a more insightful approach to material selection.

What is Ductile Iron?

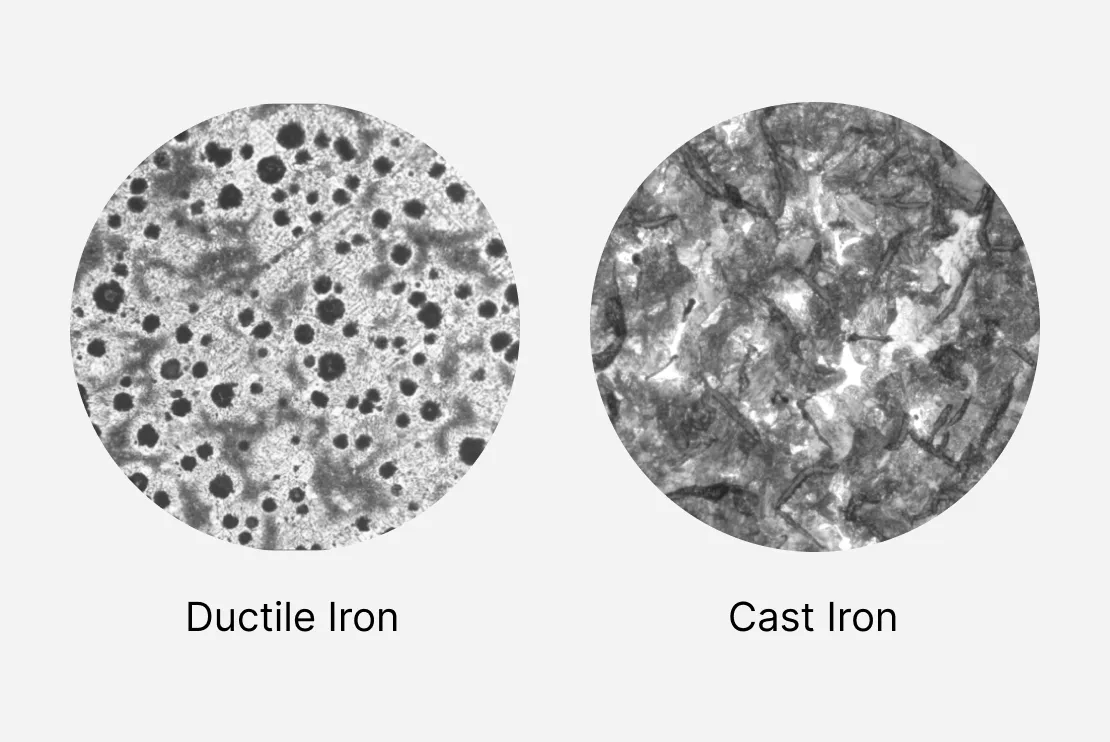

Ductile iron, also known as nodular cast iron or spheroidal graphite iron,

stands out for its remarkable properties in the realm of metallurgy. Ductile

iron is a

type of cast iron alloy distinguished by

its nodular graphite

inclusions, providing it with enhanced ductility and toughness. Unlike

traditional brittle cast iron, ductile iron exhibits a more malleable

nature, making it adaptable to a variety of applications.

A. Advantages Of Ductile Iron

I. High Strength and Durability

Ductile iron exhibits impressive tensile strength, providing robustness

and durability in applications subjected to heavy loads and stress.

II. Improved Ductility

Unlike traditional cast iron, ductile iron is more ductile and less

brittle, allowing it to deform without fracturing. This enhanced

ductility makes it resilient to sudden impacts and vibrations.

III. Excellent Machinability

Ductile iron's machinability is a key advantage, facilitating ease of

shaping, cutting, and finishing during the manufacturing process. This

makes it a preferred material for various components in the automotive

and machinery industries.

IV. Corrosion Resistance

Ductile iron's resistance to corrosion, particularly in aggressive

environments such as water and sewage systems, enhances its longevity

and reduces maintenance costs.

V. Cost-Effective

The cost-effectiveness of ductile iron lies in its combination of

strength, durability, and ease of production. It provides a

cost-efficient alternative for applications requiring the benefits of

iron without sacrificing performance.

VI. Cost-Effective

Ductile iron finds applications in a wide range of industries, including

construction, agriculture, automotive, and water infrastructure. Its

versatility makes it suitable for diverse engineering projects.

VII. Fatigue Resistance

The ability of ductile iron to withstand cyclic loading without

succumbing to fatigue failure makes it ideal for structures and

components exposed to dynamic forces over time.

B. Applications of Ductile Iron

I. Water and Sewage Systems

Ductile iron pipes are widely used for water and sewage transportation

due to their corrosion resistance and ability to withstand high-pressure

conditions.

II. Construction Industry

Ductile iron is employed in construction for applications such as:

- Structural components like beams and columns.

- Pile-driving casings for foundation support.

- Retaining walls and tunnel linings.

III. Automotive Components

Ductile iron is favored in the automotive industry for manufacturing

components like:

- Engine blocks.

- Crankshafts and camshafts.

- Suspension system parts.

IV. Agricultural Machinery

Ductile iron is used in the production of various agricultural machinery

components due to its strength and resistance to wear and tear.

V. Oil and Gas Industry

Ductile iron finds applications in the oil and gas sector for components

like valves, pumps, and pipelines, where its durability and corrosion

resistance are crucial.

VI. Railway Infrastructure

Ductile iron is utilized in the construction of railway tracks, including

components like rail chairs and brake shoes.

VII. Industrial Piping Systems

Ductile iron pipes and fittings are employed in industrial settings for

transporting fluids, chemicals, and gases due to their durability and

resistance to corrosion.

VIII. Hydraulic Systems

Ductile iron is used in the manufacturing of hydraulic components, such

as cylinders and pump housings, where strength and resistance to

pressure are essential.

IX. Marine Applications

Ductile iron is employed in marine engineering for components like ship

propellers, where its resistance to corrosion in saltwater environments

is crucial.

What is Cast Iron?

Cast iron, a strong and brittle alloy of iron, carbon, and silicon, has a

rich historical significance dating back to ancient times. Its versatility

in casting complex shapes made it a revolutionary material in the industrial

era, contributing to the development of various structures and machinery.

A. Advantages of Cast Iron

Cast iron, with its distinct properties, offers several advantages across

various applications, making it a favored material for specific uses:

I. High Strength and Durability

Cast iron possesses high compressive strength, making it ideal for

applications where resistance to heavy loads and pressure is crucial,

such as in construction and heavy machinery.

II. Heat Retention and Thermal Conductivity

Cast iron's ability to retain and evenly distribute heat makes it

suitable for cookware, providing consistent cooking temperatures and

enhancing the flavor of certain dishes.

III. Versatility in Casting Complex Shapes

The casting process of cast iron allows for intricate and complex shapes,

making it versatile for manufacturing components with detailed designs

and specifications.

IV. Cost-Effective Production

Cast iron is relatively cost-effective to produce, offering an economical

solution for applications that require strength and durability without

the high cost associated with certain alloys.

V. Excellent Wear Resistance

Cast iron exhibits excellent wear resistance, making it suitable for

applications involving friction and abrasion, such as brake rotors and

certain industrial components.

VI. Damping Properties

Cast iron's ability to absorb and dampen vibrations makes it advantageous

in applications where vibration control is essential, such as in engine

blocks and machinery.

VII. Recyclability

Cast iron is highly recyclable, contributing to sustainability efforts by

reducing the demand for raw materials and energy-intensive production

processes.

VIII. Corrosion Resistance with Alloy

Additions

Alloyed cast iron variants, or those with protective coatings,

demonstrate improved corrosion resistance, expanding their use in

environments prone to rust and degradation.

IX. Longevity and Low Maintenance

Cast iron components are known for their longevity and low maintenance

requirements, contributing to cost savings over the lifecycle of

structures or machinery.

B. Properties of Cast Iron Material

Cast iron, a versatile alloy of iron, carbon, and silicon, exhibits

distinct properties that contribute to its widespread use across various

applications:

I. High Compressive Strength

Cast iron possesses exceptional compressive strength, making it

well-suited for applications where the material must withstand heavy

loads and pressure, such as in construction and machinery components.

II. Brittleness

One characteristic of cast iron is its inherent brittleness. While this

makes it less suitable for applications requiring flexibility, it is

advantageous in situations where rigidity and stability are critical.

III. High Melting Point

Cast iron has a high melting point, allowing it to maintain structural

integrity even in environments with elevated temperatures. This property

makes it suitable for applications involving exposure to heat, such as

in engine components.

IV. Excellent Heat Retention

Cast iron's ability to absorb and retain heat evenly makes it a preferred

material for cookware, ensuring consistent cooking temperatures and

enhancing the flavors of dishes.

V. Versatility in Casting

The casting process of cast iron allows for the production of intricate

and complex shapes, providing versatility in design and enabling the

manufacturing of components with detailed specifications.

VI. Good Wear Resistance

Cast iron exhibits good wear resistance, making it suitable for

applications involving friction and abrasion. This property contributes

to its use in components like brake rotors and certain industrial

machinery parts.

VII. Vibration Damping

Cast iron possesses damping properties, meaning it can absorb and

dissipate vibrations. This characteristic makes it advantageous in

applications where vibration control is essential, such as in engine

blocks.

VIII. Corrosion Susceptibility

While cast iron can be susceptible to corrosion, certain alloyed

variations or those with protective coatings demonstrate improved

corrosion resistance. Proper maintenance and coatings are often employed

to mitigate this property.

IX. Recyclability

Cast iron is highly recyclable, contributing to sustainability efforts by

reducing the need for new raw materials and energy-intensive

manufacturing processes.

Ductile Iron vs Cast Iron

Here are the difference between ductile iron and cast iron:

| Property |

Ductile Iron |

Cast Iron |

| Composition |

Contains nodular graphite, carbon, and silicon. |

Contains graphite flakes, carbon, and silicon. |

| Strength |

Higher tensile strength and ductility. |

Higher compressive strength, but less ductile.

|

| Brittleness |

Less brittle, more malleable. |

Brittle, prone to fracture under stress. |

| Mechanical Properties |

Excellent impact resistance and toughness. |

Prone to cracking under impact, less toughness. |

| Applications |

Suitable for applications requiring flexibility. |

Suitable for applications requiring rigidity. |

| Versatility |

Versatile in casting complex shapes. |

Versatile in casting but limited in complexity. |

| Corrosion Resistance |

Resistant to corrosion in certain environments. |

Susceptible to corrosion, may need protective coatings. |

| Cost |

Generally more expensive than traditional cast iron. |

Generally cost-effective. |

| Common Uses |

Water and sewage pipes, automotive parts, construction. |

Engine blocks, pipes, manhole covers, cookware. |

| Machinability |

Exhibits good machinability, facilitating shaping and

finishing. |

May present challenges in machining due to brittleness. |

| Heat Conductivity |

Lower thermal conductivity compared to traditional cast

iron. |

Higher thermal conductivity, making it suitable for

heat-related applications. |

| Weight |

Typically lighter than cast iron. |

Generally heavier, providing stability in certain

applications. |

| Fatigue Resistance |

Resistant to fatigue failure, suitable for cyclic loading.

|

Prone to fatigue failure under repetitive stress. |

| Ductility |

Greater ability to deform without fracturing. |

Limited ductility, less capable of deformation. |

Factors Influencing Decision-Making

When deciding between ductile iron and cast iron for various applications,

several factors come into play, each influencing the final decision:

A. Considerations when choosing between ductile iron and cast iron

I. Strength Requirements

Evaluate the specific strength requirements of the application. Ductile

iron offers higher tensile strength and ductility, while cast iron

provides superior compressive strength.

II. Flexibility vs. Rigidity

Determine whether the application requires flexibility or rigidity.

Ductile iron is more malleable and suitable for applications where

deformation may occur, while cast iron is better suited for rigid

structures.

III. Mechanical Properties

Consider the mechanical properties required for the application, such as

impact resistance and toughness, which vary between ductile iron and

cast iron.

IV. Corrosion Resistance

Assess the environmental conditions and exposure to corrosion. Ductile

iron may offer better resistance to certain corrosive environments,

while cast iron may require protective coatings.

V. Machinability

Evaluate the ease of machining required for the application. Ductile iron

generally exhibits better machinability compared to cast iron.

VI. Weight Considerations

Consider the weight limitations and transportation requirements of the

application. Ductile iron is typically lighter than cast iron.

B. Cost implications and budget considerations

I. Initial Cost

Ductile iron may have a higher initial cost compared to traditional cast

iron due to its manufacturing process and superior properties.

II. Long-term Costs

Consider the long-term costs associated with maintenance, repairs, and

replacement. Ductile iron's durability and resistance to corrosion may

result in lower maintenance costs over time.

III. Total Cost of Ownership

Assess the total cost of ownership, including installation, operation,

and maintenance expenses, to make an informed decision based on budget

constraints.

C. Environmental and sustainability aspects

I. Recyclability

Both ductile iron and cast iron are highly recyclable materials,

contributing to environmental sustainability and reducing the demand for

raw materials.

II. Environmental Impact

Consider the environmental impact of production processes and material

disposal. Ductile iron may offer advantages in terms of energy

efficiency and emissions reduction.

III. Resource Conservation

Evaluate the use of natural resources and energy consumption associated

with the production of ductile iron and cast iron, aiming to minimize

environmental impact and promote sustainability.

Conclusion

In summary, the distinction between ductile iron and cast iron hinges on

specific strengths and applications. It underscores the importance of a

nuanced understanding for informed decision-making. Whether prioritizing

flexibility with ductile iron or rigidity with cast iron, a well-informed

choice ensures optimal performance aligned with project goals.