Introduction

Understanding the difference between cast iron and iron is essential for

making informed decisions in various applications, from cooking to

construction. Both materials have unique properties and uses; this guide

will help you grasp the key distinctions.

Is Cast Iron the Same as Iron?

No, cast iron is not the same as iron. While both are forms of iron, cast

iron contains a higher carbon content, making it heavier, more brittle, and

better at heat retention compared to pure iron.

Before diving into the difference, we will understand what cast iron is and

what iron is.

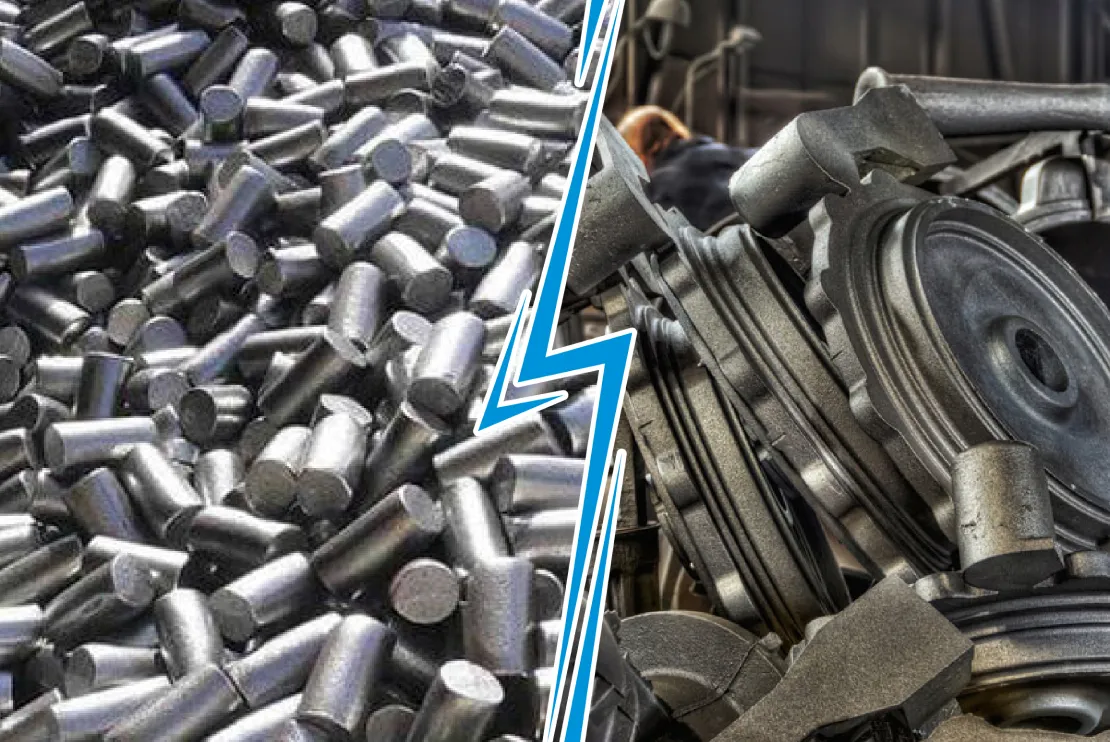

What is Cast Iron?

Cast iron is a type of iron alloy that contains a higher carbon content than

other forms of iron. This carbon content, typically between 2-4%, along with

other alloying elements such as silicon, gives cast iron its distinctive

properties.

A. Characteristics of Cast Iron

1. High Carbon Content

The elevated carbon content distinguishes cast iron from other iron

alloys. This imparts unique properties to the material.

2. Brittleness

Cast iron tends to be brittle, meaning it can fracture or crack under

sudden stress or impact. However, it is exceptionally strong under

compression.

3. Cast Iron Density

Cast iron is denser and heavier than many other metals, which contributes

to its durability and heat retention properties.

Learn more about Cast Iron Density.

4. Excellent Heat Retention

One of the most notable characteristics of cast iron is its ability to

retain heat. This property makes it ideal for applications where heat

retention is essential, such as in cookware.

5. Versatility

Cast iron can be cast into a variety of shapes and forms, making it

suitable for a wide range of applications.

B. Common Uses of Cast Iron

Cast iron finds application in various industries and products due to its

unique properties:

1. Cookware

Cast iron skillets, pans, and pots are popular for their excellent heat

retention and even heat distribution, making them ideal for cooking.

2. Pipes and Fittings

Cast iron pipes are commonly used in plumbing systems due to their

durability and resistance to corrosion.

3. Machinery and Engine Parts

Cast iron is utilized in the manufacturing of heavy-duty machinery parts,

such as engine blocks, cylinder heads, and gears, owing to its strength

and wear resistance.

C. Advantages of Cast Iron

Cast iron finds application in various industries and products due to its

unique properties:

1. Durability

Cast iron is highly durable and resistant to wear and tear, making it

suitable for long-lasting applications.

2. Heat Retention

Its ability to retain heat makes cast iron ideal for cooking utensils and

machinery components that require thermal stability.

3. Versatility

Cast iron can be cast into complex shapes, allowing for intricate designs

and customized components.

D. Disadvantages of Cast Iron

1. Brittleness

Cast iron's brittleness can be a drawback in applications where impact

resistance is crucial, as it may fracture under sudden stress.

2. Prone to Rust

If not properly maintained, cast iron can rust over time, especially in

environments with high humidity or exposure to moisture.

3. Heavyweight

Cast iron is denser and heavier compared to other materials, which may

limit its use in certain applications where weight is a concern.

What is Iron?

Iron is a chemical element that is widely used in various forms, including

cast iron and wrought iron. Pure iron is relatively soft and malleable.

A. Characteristics of Iron

1. Ductility

Iron is ductile, meaning it can be drawn into thin wires without losing

its strength. This property makes it suitable for a wide range of

applications.

2. Strength

Iron is inherently strong, especially in tension. This strength makes it

ideal for structural components and load-bearing applications.

3. Malleability

Iron is malleable, meaning it can be hammered or rolled into thin sheets

without breaking. This property allows it to be easily formed into

different shapes and structures.

4. Magnetic Properties

Iron is ferromagnetic, meaning it can be magnetized. This property is

utilized in various electronic devices and applications.

B. Common Uses of Iron

Iron finds widespread use across various industries and applications due

to its versatility and abundance:

1. Construction

Iron is a fundamental material in construction, used for structural

components such as beams, columns, and reinforcement bars (rebar).

2. Automotive Industry

Iron is used extensively in the automotive sector for manufacturing car

bodies, engine blocks, and various components.

3. Machinery and Equipment

Iron is essential for the production of machinery, tools, and equipment

used in manufacturing, agriculture, and other sectors.

4. Household Products

Iron is used in the production of everyday household items such as

appliances, furniture, and utensils.

C. Advantages of Iron

1. Versatility

Iron's versatility allows it to be used in a wide range of applications,

from construction to manufacturing.

2. Strength

Iron is inherently strong, making it suitable for load-bearing structures

and heavy-duty applications.

3. Abundance

Iron is one of the most abundant elements on Earth, making it readily

available and cost-effective.

D. Disadvantages of Iron

1. Corrosion

Iron is prone to rust and corrosion when exposed to moisture and oxygen,

which can degrade its structural integrity over time.

2. Weight

Iron is relatively dense and heavy compared to other materials, which can

limit its use in applications where weight is a concern.

3. Processing

Extracting and processing iron ore into usable forms can be

energy-intensive and environmentally impactful, contributing to carbon

emissions and other environmental issues.

Difference Between Cast Iron and iron

Here are a key difference between cast iron and iron:

| Attribute |

Cast Iron |

Iron |

| Composition |

Iron with 2-4% carbon |

Pure iron or with minimal carbon |

| Weight |

Heavier |

Lighter

|

| Strength |

Brittle, strong under compression |

Ductile, strong in tension |

| Durability |

Excellent, but prone to rust |

Very durable, also prone to rust |

| Heat Retention |

High |

Moderate |

| Cost |

Generally more expensive |

Generally less expensive |

| Common Applications |

Cookware, pipes, machinery parts |

Structural, automotive, tools |

| Machinability |

Difficult |

Relatively easier |

| Corrosion Resistance |

Susceptible to rust |

Prone to rust, requires a protective coating |

| Thermal Conductivity |

Lower |

Higher |

Cast iron vs iron: which is better?

Choosing between iron and cast iron depends on the specific application and

the properties required. Each material has its strengths and weaknesses,

making them suitable for different uses. Here’s a guide to help you decide

which is better for your needs.

A. Factors to Consider When Choosing Between Iron and Cast Iron

1. Application

Determine the purpose for which you need the material. For instance,

cooking requires different properties than construction.

2. Strength Requirements

Consider whether the material needs to withstand tension or compression.

3. Weight Constraints

Evaluate if the weight of the material is a critical factor in your

application.

4. Durability

Assess the environmental conditions, such as exposure to moisture, that

could lead to rust and corrosion.

5. Cost

Budget considerations can influence your choice, as the materials have

different costs.

6. Machinability

Think about how easy it needs to be to shape and work with the material.

B. Use Cast Iron When

1. Cooking

Cast iron is ideal for cookware like skillets, Dutch ovens, and griddles

due to its excellent heat retention and even heating.

2. Plumbing

Cast iron pipes are durable and commonly used in plumbing for water and

sewage systems.

3. Heavy Machinery

For components that need to be strong under compression, such as engine

blocks and machinery parts, cast iron is a good choice.

C. Use Iron When

1. Construction

Iron is widely used in construction for beams, columns, and reinforcement

bars due to its strength and versatility.

2. Automotive Industry

Iron is used for car bodies and parts, providing the necessary strength

and durability while being relatively lightweight.

3. Tools and Hardware

For tools and other hardware, iron’s ductility and machinability make it

suitable for producing durable and effective products.

Conclusion

Choosing between cast iron and iron depends on your needs. Cast iron is great

for cookware and heavy-duty parts due to its heat retention and durability,

but it's brittle and can rust. Iron is versatile and strong, ideal for

construction and automotive uses, though it needs protection from corrosion.

Consider your specific application, strength, weight, durability, and cost

to make the best choice. If you have questions, feel free to reach out.